Scrap iron shredder

【Motor Power】:2*11-2*90kw

【Production capacity】:2T/h-8T/h

【Discharge size】:The coarse crushing effect is determined by the number of tool claws

【Supporting equipment】:Shredder host, power distribution cabinet, reducer * 2, motor * 2, magnetic separator, eddy current separator (optional)

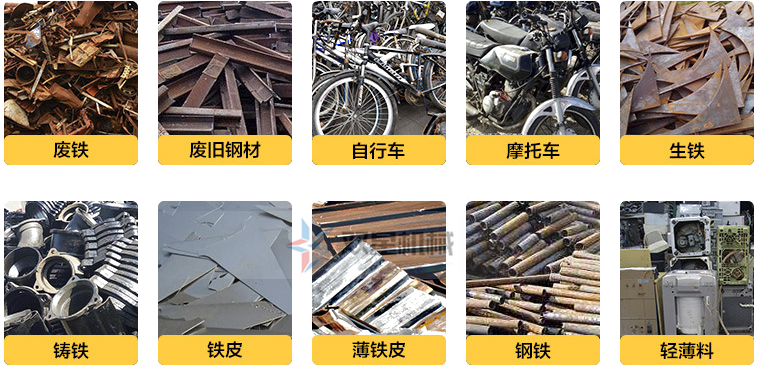

【Applicable materials】:Suitable for various materials such as waste cars, waste motorcycles, waste electric bicycles, waste oil drums, paint buckets, colored steel tiles, and iron sheets

【Scrap iron shredder Price】:(Please refer to the parameter price list below for details)

Telephone:13592521219

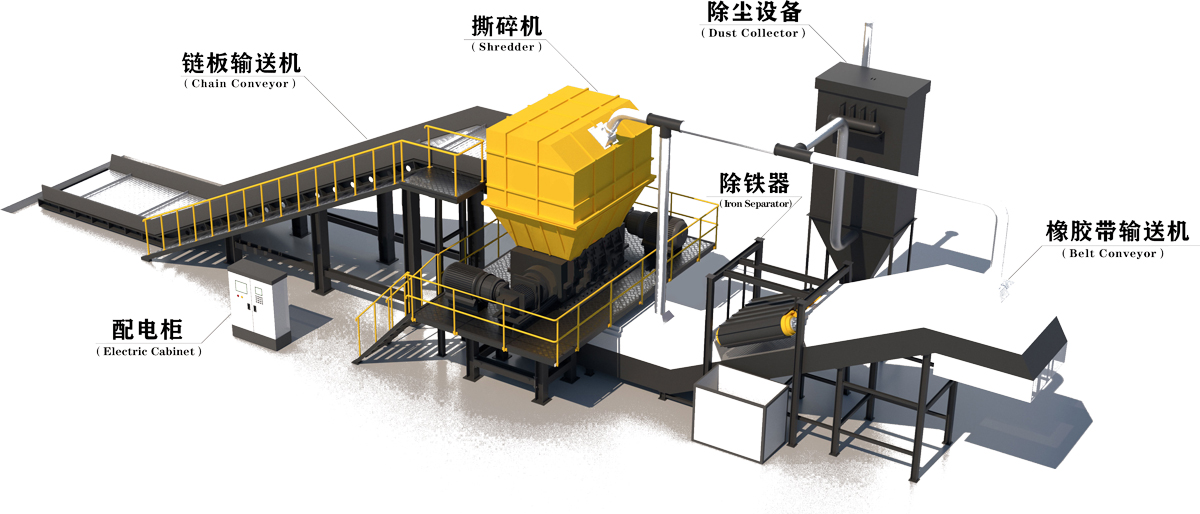

01. Equipment

1. Raw material inlet box: The main body is welded with Q235 steel plate, which is processed as a whole after stress relief treatment to ensure the stability of the equipment during long-term high load operation;

2. Moving and fixed cutting tools: The moving tool material is made of special alloy tool steel forged blanks, which have undergone precision machining and multiple heat treatments. The overall toughness and hardness are consistent, and can be repeatedly repaired and used, ensuring its cutting performance and service life;

3. Bearings/Seals: The bearings are installed in a sealed manner, which is easy to maintain and replace. The unique sealing structure effectively blocks the pollution of metal debris, protects the bearings, and improves their service life;

4. Spindle: Made of high-strength heavy-duty special steel for processing and refining, without deformation, providing strong guarantee for cutting;

5. Rack raw material inlet: It can be customized for personalized processing in accordance with customer site planning and feeding habits, and more reasonably integrated into production line scale production;

02. Working principle

Production line process of scrap iron shredder

03. Equipment advantages

1. The shell of the scrap iron shredder is welded with 35mm-50mm manganese steel plate, which is sturdy and durable;

2. The equipment has a compact structure, safety and durability, high production efficiency, low energy consumption, good quality shredded products, and low processing costs;

3. For various large scrap metal materials such as used cars, bicycles, motorcycles, etc., one-time shredding treatment is carried out without the need for pre-treatment. At the same time, Double Star Machinery supports customized scrap iron shredder equipment of various models;

4. The scrap iron shredder adopts a dual axis structure design, with high torque, strong shredding power, and no noise during the shredding process;

5. The optimized design of the tool holder enables the claw type cutter to disperse the force, which increases the shear force of each blade, which is suitable for tearing up various scrap iron metal materials, effectively improving the cutting force of the cutter and reducing tool wear.

04. Equipment price and model

Scrap iron shredder is beneficial for environmental protection and the recycling of scrap iron resources. It can forcefully shred various waste metal materials, driving the entire process of scrap metal recycling and reuse. Scrap iron shredder provides customers with favorable shredding tools and also brings higher profit value. It is the most satisfactory and popular equipment in the industry.

05. Related Cases+More

△ 您可能對(duì)以下產(chǎn)品感興趣?

說(shuō)點(diǎn)什么吧

- 全部評(píng)論(0)

還沒(méi)有評(píng)論,快來(lái)?yè)屔嘲l(fā)吧!